LOVE TO DO

Integration

DEVELOPMENT

Project

EDUCATION

Major in Power machine engineering

Master. Major in Electric control system

EXPERIENCE

Corning Display

Global team management and Asia team building up

Force instrument

Startup company from Academia Sinica.

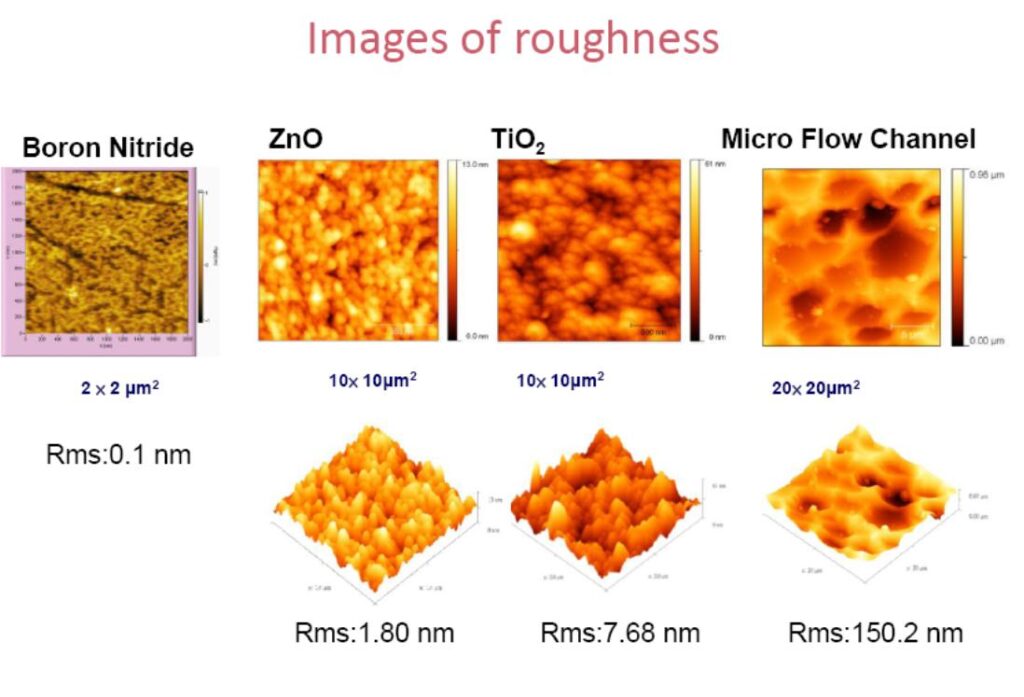

Nano spec measure instruments design from zero, including AFM/SPM, profilometer, Lock-in amplifier, nano XY stage, and AOI for PSS(PATTERN SAPPHIRE SUBSTRATE).

FOXCONN Inc.

Robot cell design for auto defect checking and packing

- Boost Your Project Management Efficiency with ChatGPT: Tips and Tools

- Profilemetor

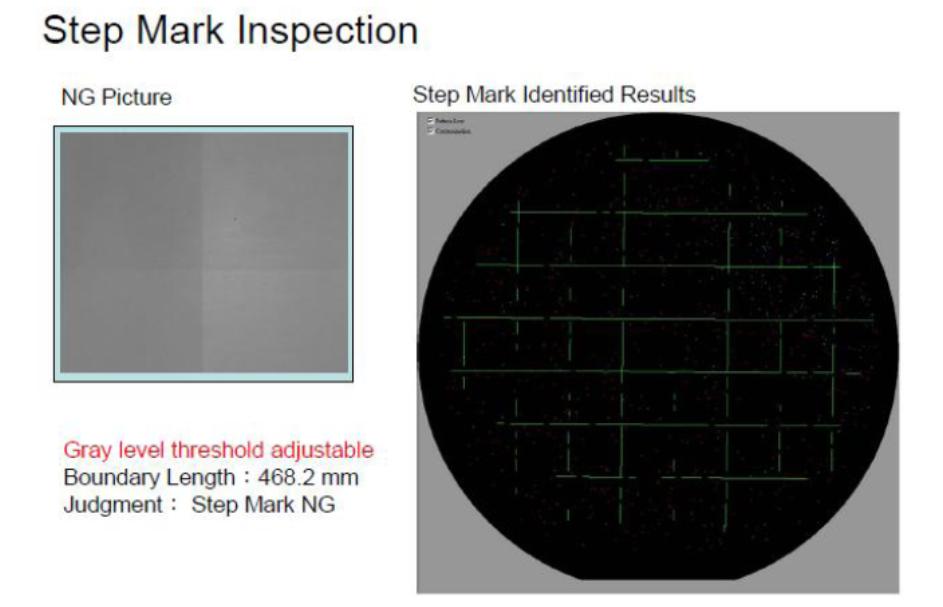

- AOI - Auto optical inspection

- AFM - Atom Force Microscope

- Strengths

Here are some specific ways that you can use ChatGPT to improve your work efficiency as a project manager:

- Use ChatGPT for quick research on specific project-related topics.

- Use ChatGPT to automate responses to frequently asked questions or send reminders to team members.

- Use ChatGPT to schedule meetings and set reminders for deadlines.

- Use ChatGPT to manage tasks, track progress and stay organized.

By incorporating ChatGPT into your workflow, you can save time and be more productive in your role as a project manager.

One tool you can use to automate responses and send reminders to team members is a chatbot platform such as ManyChat, Chatfuel, or Tars. These platforms allow you to create chatbots that can be integrated with popular messaging apps such as Facebook Messenger, WhatsApp, and Slack.

With these chatbot platforms, you can create automated responses to common questions, provide updates on project status, and send reminders to team members about upcoming deadlines or meetings. You can also use these platforms to gather feedback from team members and provide them with resources and information they need to complete their tasks.

These chatbot platforms offer a range of features and integrations that can help you improve your communication and collaboration with your team, ultimately leading to increased work efficiency as a project manager.

Design for different sample request. Resolution can achieve Nano meter. 100% design including HW and SW in Force inc.

LED PSS defect inspection in Force instrument

AFM(atom force microscope). Capable to measure surface profile in Nano meter (0.000000001mm)

100% design and manufacturing in Taiwan

More introduction:https://en.wikipedia.org/wiki/Atomic_force_microscop

System integration on measurement and control system with production

Rich experience on system integration including software, mechanical, date/signal communication, and how to use it on process.

Capable to build up measurement and control system from 0 - ex: building up process tools from concept to migration and combine with control system including all hand-over document and coordinate with process team to provide process guide line.

Team builder. Deputy resource and vendor resource build up for schedule flexibility.

Organization capability to group up team from different function to meet project objective

Group up and scope design change into cross-functional team

Willing to train member to be project leader by guiding them to work on trial & migration project to build up their capability and enable resource's flexibility

Deputy team build up to meet each project schedule when conflict.

Technology road map build up and strategy on technical migration

Build up process measurement and control technical road map

Capable to identify gap in process issue and deliver technology to fix the gap

- Key measurement technology migration for process auto control to improve OEE in display

--Process monitor tool for quality alarm.

--Edge inspection build up and future process control

--Defect detection migration for lose prevention. - Process understanding and customer-based thinking

Well understanding on process through multiple join ventures project.

Capable to design measurement and control system that meet process need.

in 2020, 3 process control by using gauges has been trial or migrate successfully through coordinating with process

SKILLS